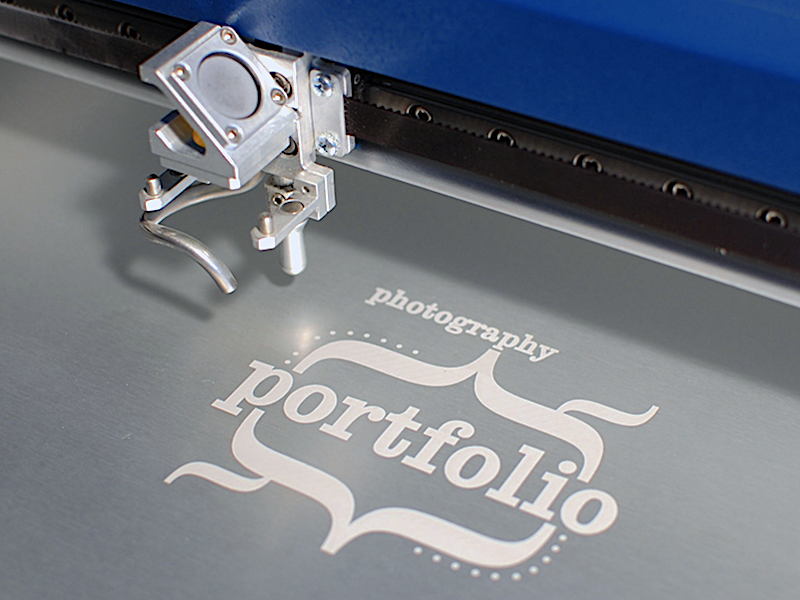

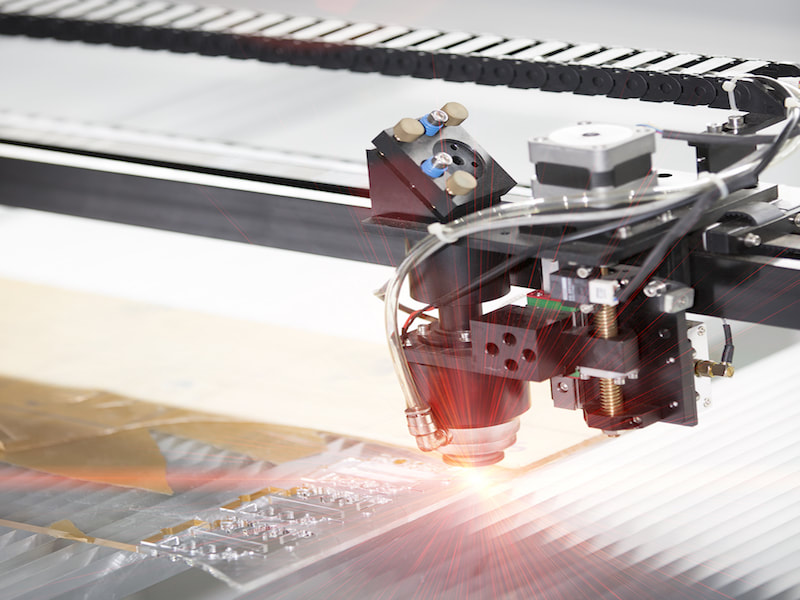

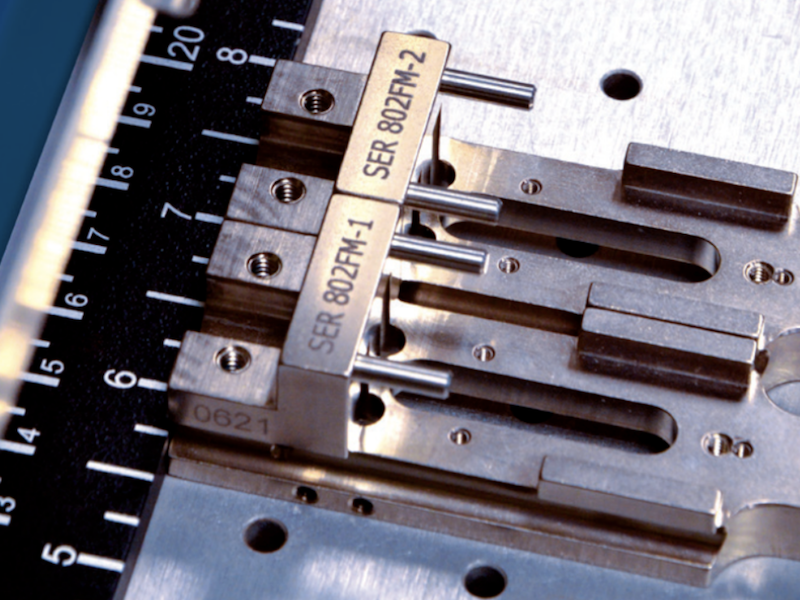

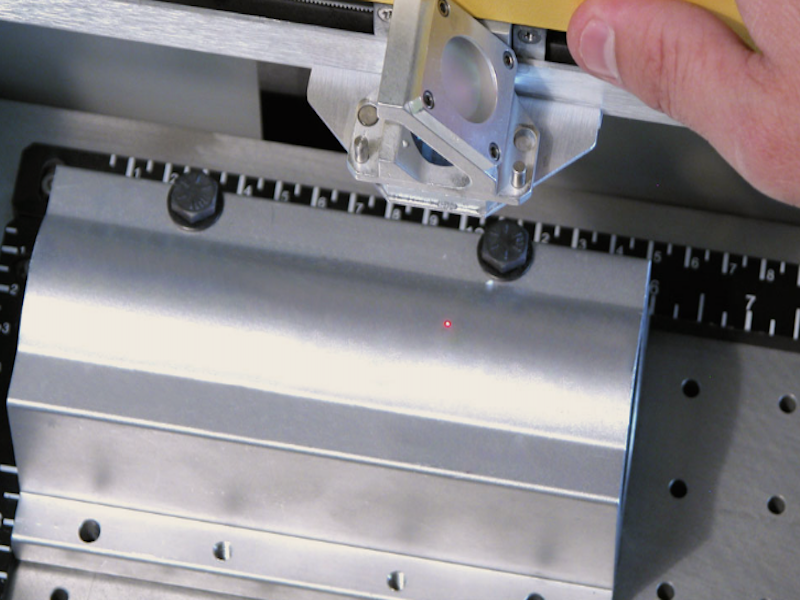

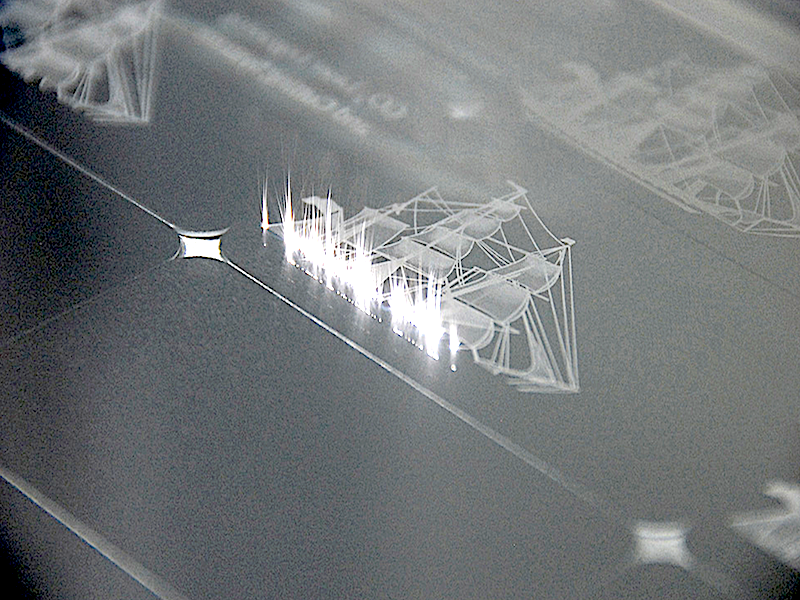

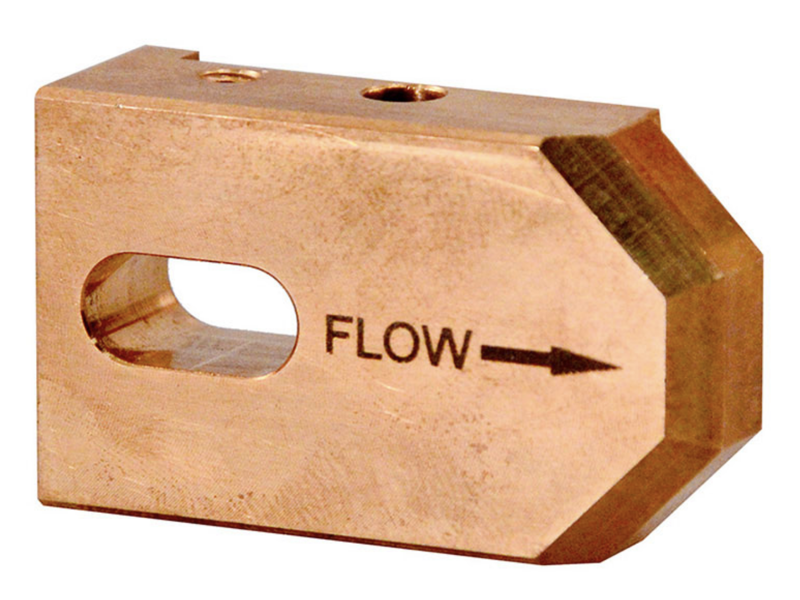

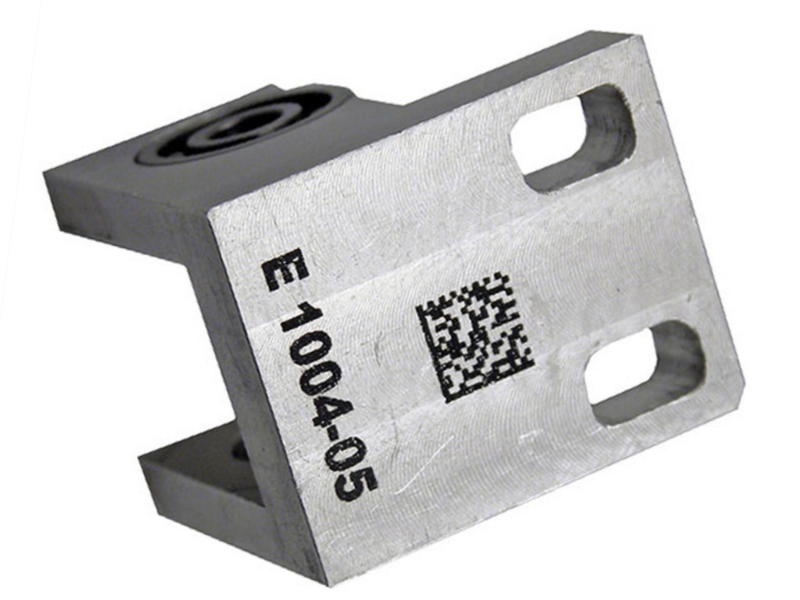

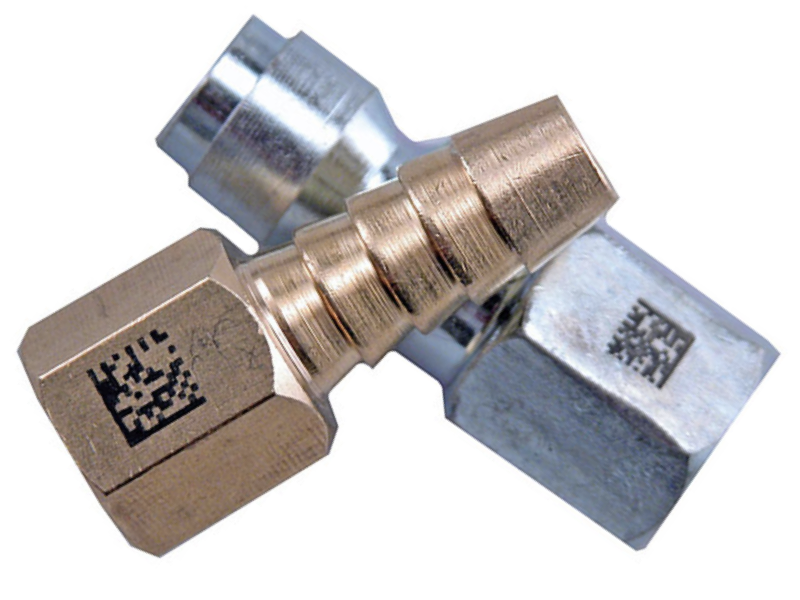

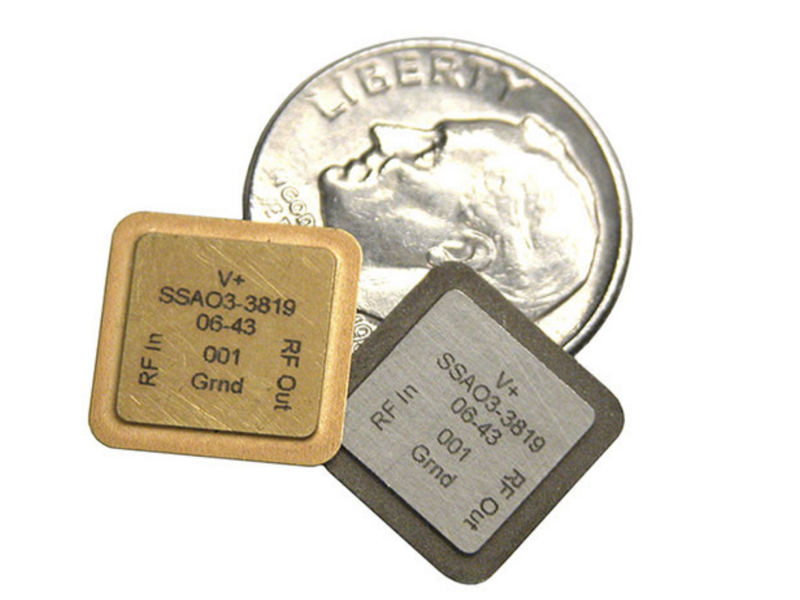

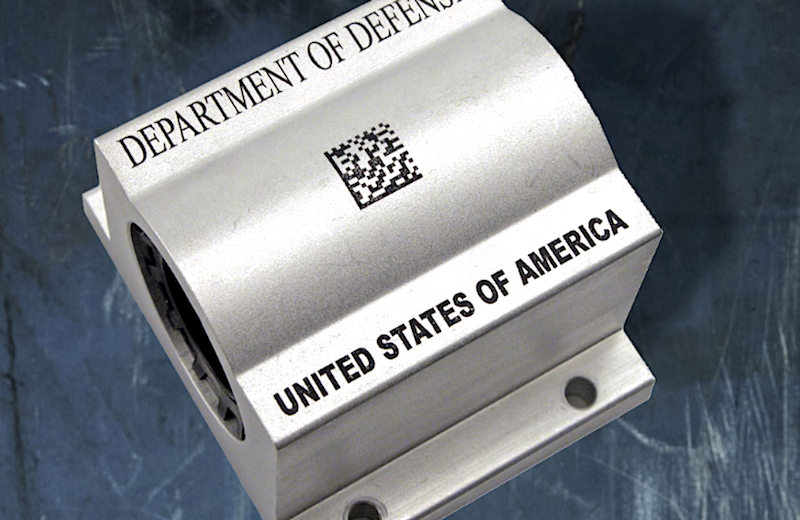

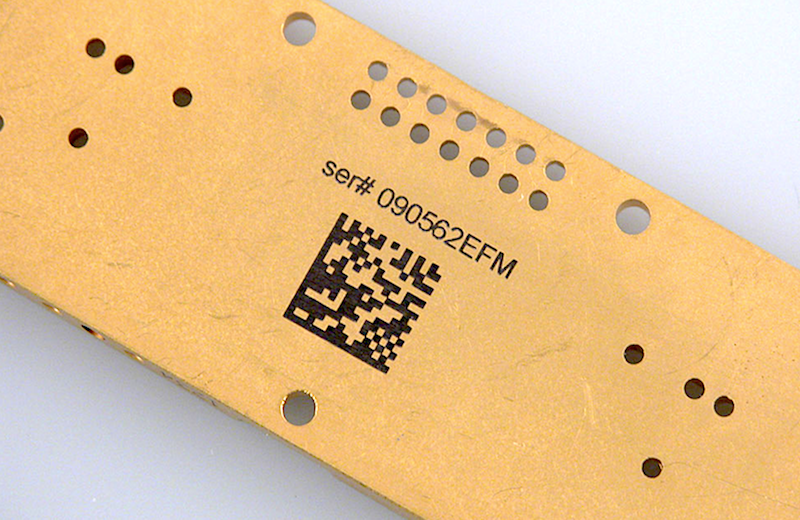

Laser Engraving penetrates the surface of the material, evaporating the material itself and leaves a permanent, durable and accurate mark on the material’s surface. Laser engraving is ideal for coated metals, wood, plastics, rubber, acrylic, glass and other surfaces. Click here for our MATERIALS page to learn more about just some of the materials we can engrave. Precision and accuracy are the hallmarks of laser engraving. Characters, letters, numbers and patterns can be clearly and exactly replicated repeatedly. As no moving parts come into contact with or touch the material, the margin of error is significantly eliminated. Only the actual beam makes contact with the material, which does not move it at all. Another key advantage of laser engraving is the small and ultra-fine scale it achieves. Fonts as small as 2.5 pt. can be clearly and permanently engraved onto materials. With our Fusion M2 32, Micron Surface Innovations can create and recreate precise, accurate and long lasting engravings which can be repeated exactly on large run orders.