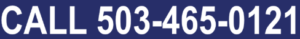

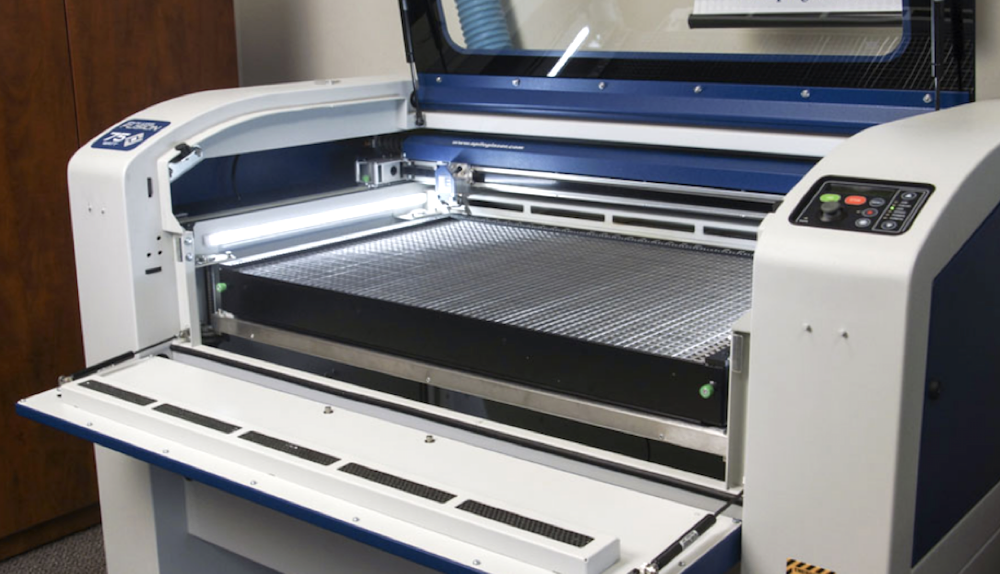

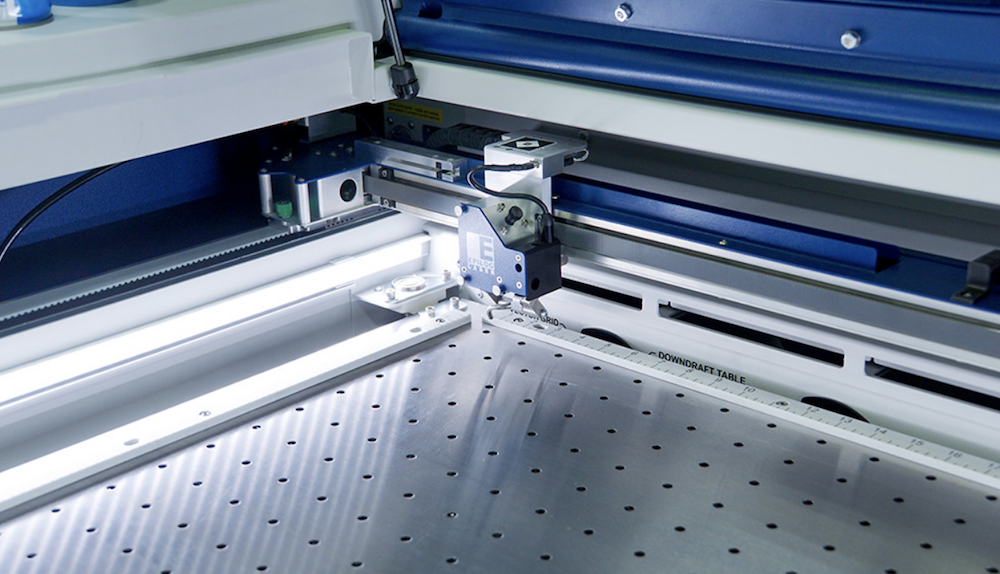

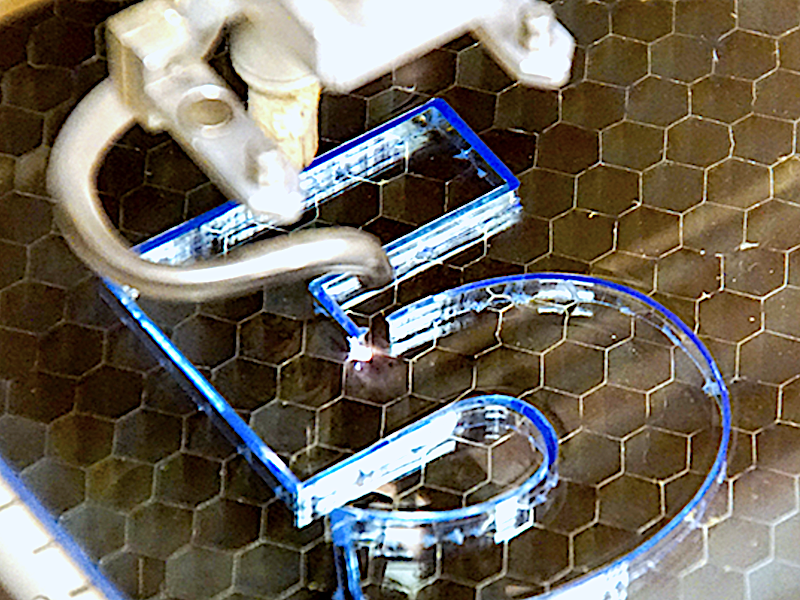

LASER MARKING | LASER ENGRAVING | LASER CUTTING

FROM MICRON SURFACE INNOVATIONS

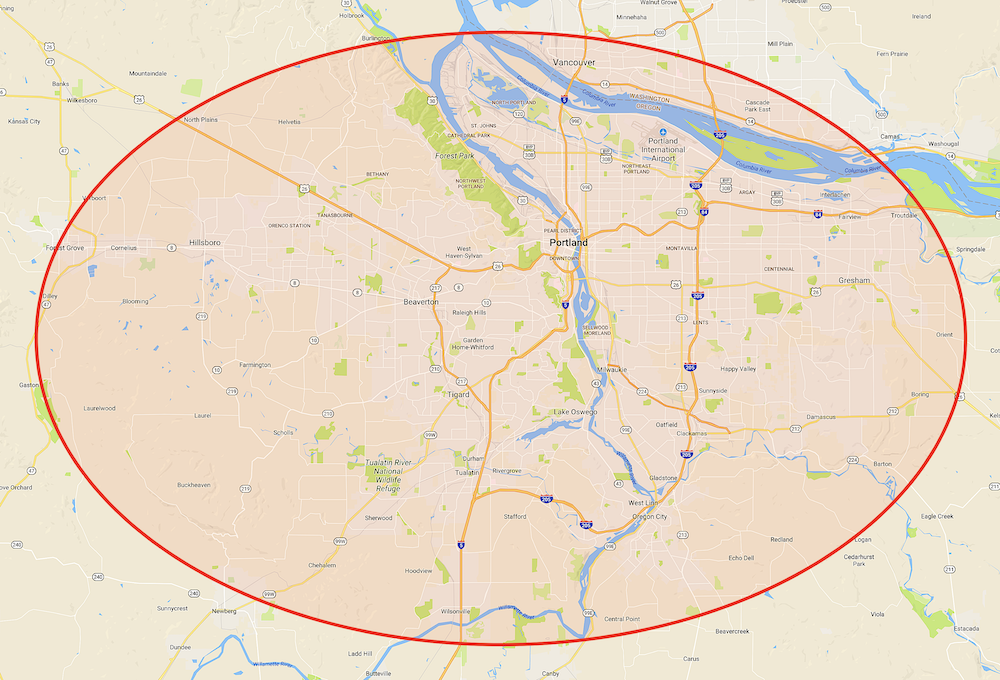

MICRON SURFACE INNOVATIONS, BASED IN PORTLAND, OREGON, OFFERS PRECISION LASER MARKING SERVICES, LASER ENGRAVING AND LASER CUTTING TO CUSTOMERS ACROSS THE UNITED STATES.

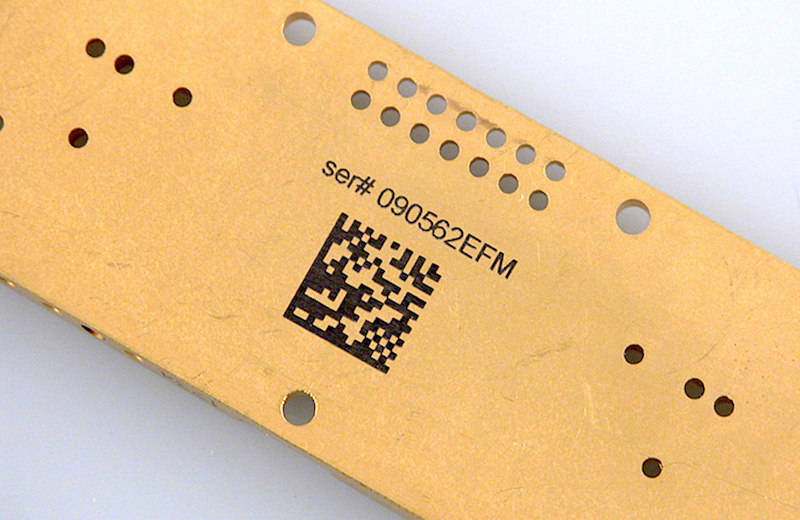

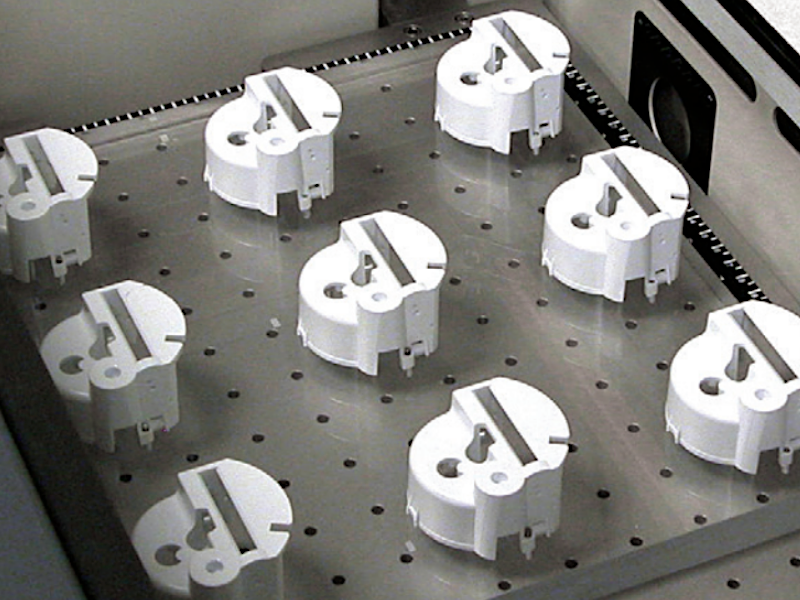

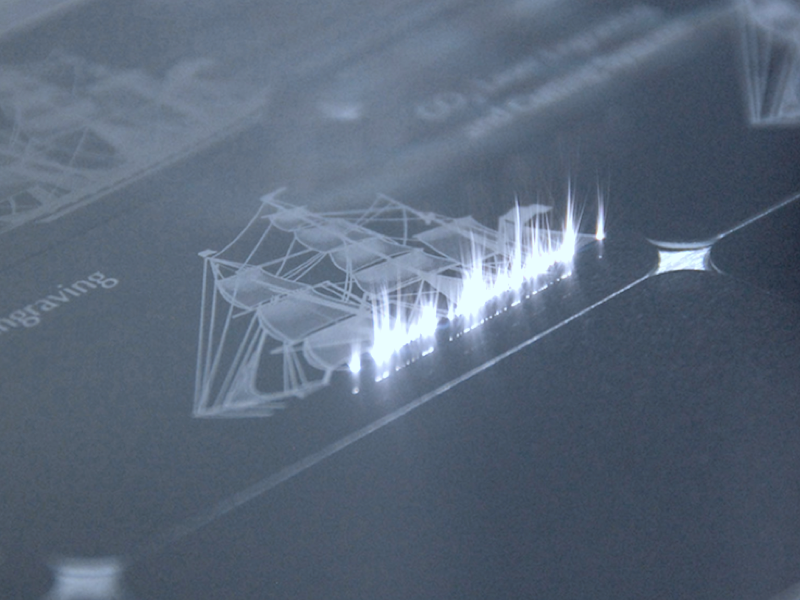

LASER MARKING

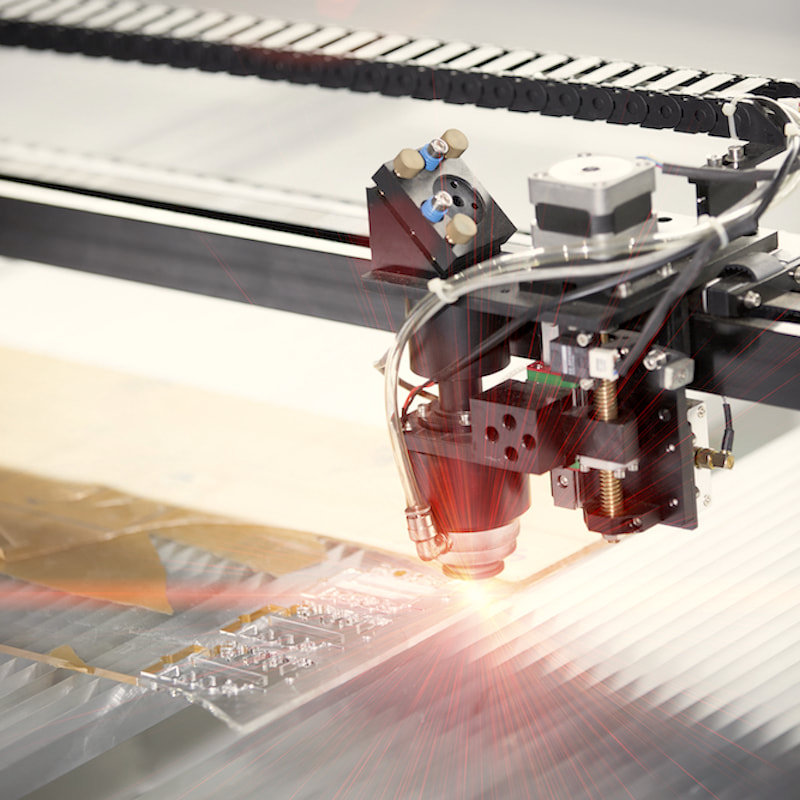

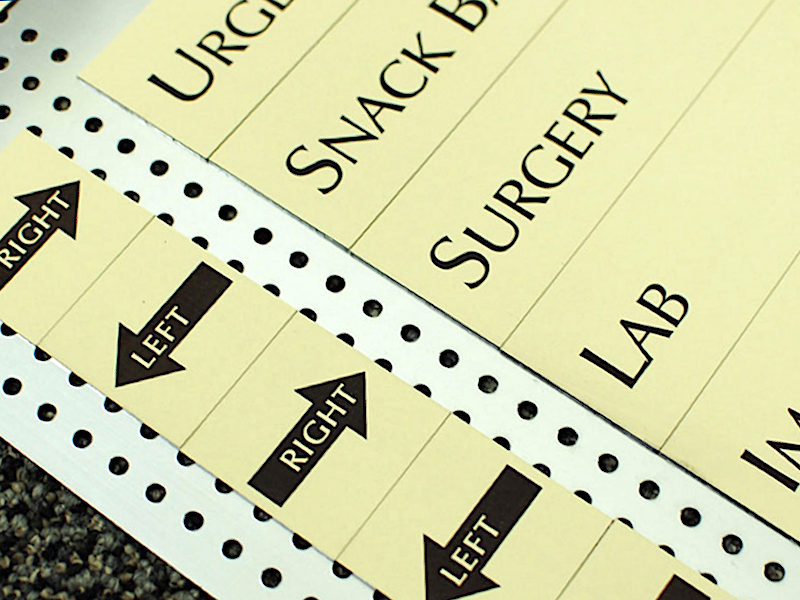

LASER ENGRAVING

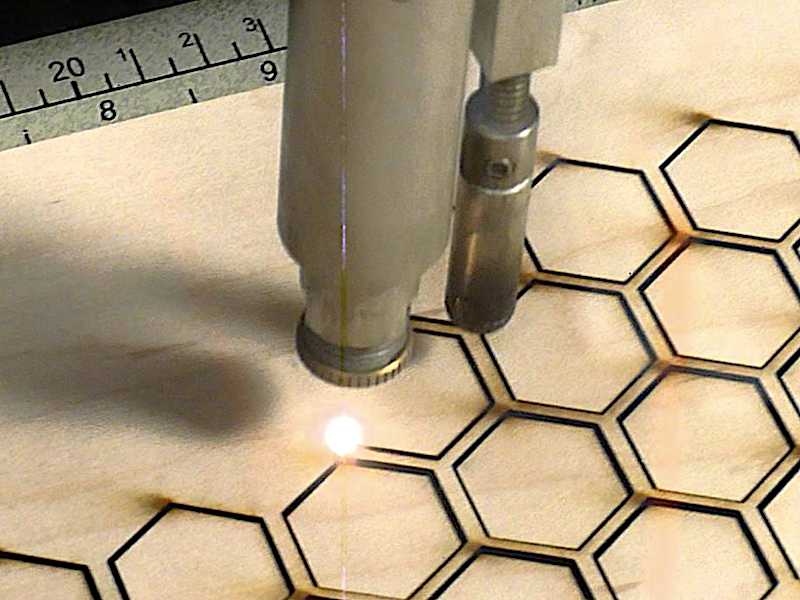

LASER CUTTING

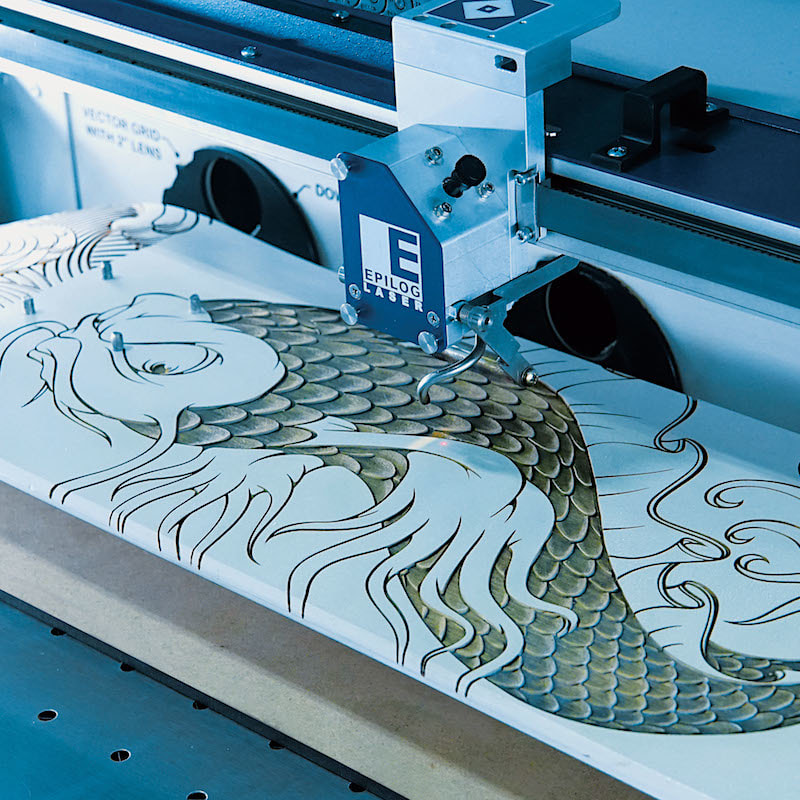

We encourage you to contact us directly at 503-465-0121 or email us at info@msi-pdx.com to discuss your project. We can offer a free estimate on cost and time for completion based on your needs and specifications. Micron Surface Innovations is a premier provider of industrial laser cutting and laser marking services, working with customers all over the United States. MSI can handle the largest jobs quickly and efficiently with precision accuracy and ship the finished projected anywhere throughout the country.